There are moments in wholesale work when a store shows interest in a new product line but refuses to buy upfront. This is where consignment inventory enters the conversation. A buyer might say something like this, “Send us the stock, and we will pay you after it sells.” When you hear that request, you know the deal has shifted into a different setup because the placement is tempting, yet the risk stays with you.

This puts wholesalers in a strange spot because visibility sounds great, yet the sales pace becomes unpredictable. You want the chance to get your products into their location since placement can lead to repeat orders. At the same time, you worry about slow movement, unclear reporting, and long waits before you see payment.

This article explains everything you need to learn about consignment inventory so you know what it means for your daily operations. You will learn when the setup makes sense, how it affects your margin, and how to avoid silent losses caused by weak reporting or misplaced stock. In the next sections, you will learn how to prevent issues so the setup does not weaken your margins over time.

Let’s get to it!

What Is Consignment Inventory?

According to NetSuite, consignment inventory is a supply chain model in which a retailer agrees to sell a product, but the supplier retains ownership of the product until it has been sold to a customer. The idea sounds easy at first, yet many wholesalers only understand how it works once they actually try it.

In this setup, the wholesaler or supplier retains ownership of the goods until the items are sold at the customer’s location. The stock sits inside the retailer’s shop, warehouse, clinic, or any selling point, yet it still belongs to you. This arrangement changes how you approach inventory management because the products sit outside your space while remaining part of your records.

Meanwhile, standard wholesale works in a very different way. The retailer pays upfront, owns the stock right away, and takes on all the sales risk. With consignment inventory, the risk shifts to you since you only get paid for the units that actually move.

You may also read about “Effective Inventory Management: 5 Strategies To Avoid Overstocks and Understocks.”

Key parties and terms to define early

You will hear three words often when dealing with this model.

“Consignor” is the supplier or wholesaler, which is you.

“Consignee” is the retailer or customer holding your stock.

“Consignment agreement” is the written document that lays out how both sides will handle the items.

These roles shape how you approach consignment inventory management because each person in the process has different responsibilities.

Why Wholesalers Consider Consignment (And When It Makes Sense)

Potential upsides for wholesalers

Although the setup brings extra work, it can also open doors that would stay closed under standard wholesale terms. When you look at the model with clear eyes, you start seeing the moments where it supports growth and the moments where it creates unnecessary pressure.

One clear advantage is increased market access. Some accounts are hard to reach because they only carry items they already trust. When you offer a low-risk setup, you give them a reason to place your products on their shelves. This helps with visibility because buyers inside the store can finally see your items.

In addition, this model works well when you want to test new products or new markets. You can send a small set and watch how they perform. This helps your inventory management process because real sales data shows which SKUs are worth a bigger push later.

Benefits for retailers and customers

Retailers welcome this model because it protects their cash flow. They get fresh products without placing a large payment upfront. This helps them test new categories with less stress.

The setup also lowers the pressure to clear items too fast. Since they do not own the stock, they avoid early markdowns. They can wait for natural sales instead of rushing to move items that may need more time on the shelf.

When consignment is a good fit

Although consignment inventory has advantages, it only works in the right conditions. You need solid data and confidence that your items actually sell. You also need enough room in your finances to handle a longer payment cycle because you wait until items move before you receive money.

This model also makes sense when the account has real value. If the customer has strong foot traffic or a loyal base, placing your goods there can help you in the long run.

Another key requirement is the ability to track items leaving your warehouse. Good consignment inventory management helps you stay aware of counts per location. Without this, you risk missing sales or losing track of products that never return.

Since the setup demands clear reporting and regular communication, it should never be something you offer to every small store. The model only works when you can handle the extra steps that come with managing inventory in more than one place.

You may also read: How To Leverage Inventory Forecasting For Customer Satisfaction.

Risks, Downsides, And Common Consignment Mistakes

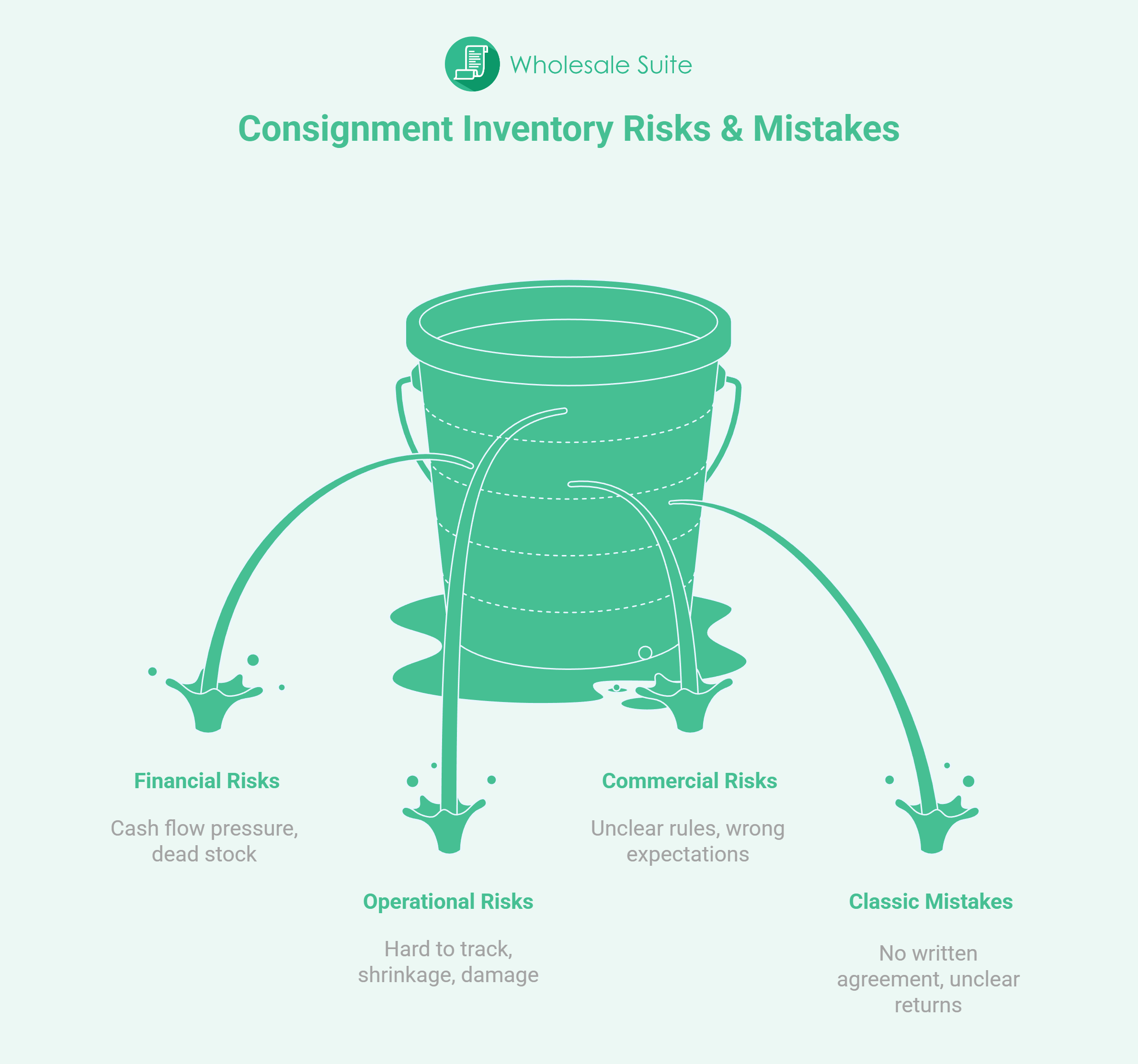

Financial and cash flow risks

When you agree to consignment inventory, you hold the risk while the customer holds the stock. This creates pressure on your cash flow since the items stay on your books until they sell. If the products move slowly, you carry the cost for a long time. This delays your plans because money that could support other parts of your inventory management process stays locked in those items.

There is also the risk of dead stock. When certain SKUs do not move, you end up with units sitting in someone else’s store while your capital stays frozen. Since payment only comes after reconciliation, long gaps between counts can create delays that push your cash cycle even further.

Operational and control risks

Although this model helps some accounts try your products, it comes with problems on the operational side. You do not see the items every day because they stay inside the consignee’s space. Since you are not there, it becomes harder to track what sold and what stayed on the shelf. This affects your ability to manage consignment inventory with accuracy.

There may also be cases of shrinkage, damage, or loss. When this happens, you have to investigate the cause because the goods still belong to you. If reports are incomplete, the issue becomes harder to sort out. This can lead to long conversations with the customer, especially when both sides have different records.

Commercial and relationship risks

This model can also affect the working relationship if the rules are unclear. When margins are not protected, you might end up losing money without noticing it. Some stores may apply “quiet discounts” or give away samples to move the product faster. If the agreement does not explain how these actions affect payout, you may receive smaller payments than expected.

There is also the risk of setting the wrong expectation. When a store gets used to this setup, they may avoid switching to standard wholesale. This creates a pattern where the customer enjoys low risk while you carry most of the weight. The longer this continues, the harder it becomes to shift the relationship back into a normal buying cycle.

Classic mistakes to call out

Some wholesalers treat consignment inventory as a casual favor. This leads to avoidable errors that create long-term problems. One common mistake is working without a written agreement. When the rules are not written down, both sides may have different ideas about how the setup works.

Another mistake is failing to explain how returns, damaged items, and markdowns should be handled. Without these details, disagreements show up near the end of the cycle. There are also cases where wholesalers forget to agree on who pays for shipping in and shipping back. This creates surprise costs that cut into your margin.

The last common mistake is letting the process run without structure. When you do not check counts or track movement, the model becomes messy. Since you are managing inventory across multiple locations, you need regular updates to avoid hidden losses.

You may also read: How To Generate A Wholesale Agreement For Your Online Store.

Designing A Solid Consignment Inventory Agreement

Non-negotiables to include

When you work with consignment inventory, the agreement sets the tone for the entire relationship. It guides how you handle stock, payments, and expectations on both sides. Since you carry most of the risk, the document needs to be clear. One key detail is the duration of the consignment period. Both sides should know how long the items will stay in the store before the terms get reviewed.

You also need to state ownership in simple wording. The products belong to you until they sell. This guides how you approach inventory management because the items sit in the consignee’s location while your records still track them. You also need to outline how often counts happen. Some stores send weekly reports while others follow a monthly cycle. This matters because the pace of reporting affects your cash flow.

Payment terms must also be written in a way that avoids confusion. Many wholesalers set fixed settlement cycles based on sales reports. The agreement should also explain what happens to unsold items. Some stores return them while others request a transfer to a different branch.

Operational rules and responsibilities

Clear responsibilities prevent problems later. Since the consignee displays your items, they need to follow simple rules related to placement and handling. They also need to check dates when you sell food, cosmetics, or other items with shelf life. This helps you manage consignment inventory with fewer surprises because both sides care for the stock.

Another key point is sales reporting. Some stores can export POS data while others rely on manual counts. You need to agree on the format so you can update your records properly. This helps you keep track of movement and stay aware of how each location performs.

Pricing and discount boundaries

Clear pricing rules protect your margin. You need to explain who can approve discounts and how these decisions affect payout. Some wholesalers offer slightly different prices for consignment to cover the extra steps required in managing inventory across several locations. This should be clear from the start.

Markdown rules also need to be listed. When a store lowers prices without telling you, your payout may shrink. This creates tension because the numbers no longer match your expectations. When these rules appear in writing, both sides know how pricing decisions affect final payment.

You may also read about: The Complete Guide To Wholesale Price (How To Calculate).

Approximating Consignment Workflows In WooCommerce With Wholesale Suite

Segment consignment partners using wholesale roles

WooCommerce does not run a full accounting system, yet you can still support parts of a consignment inventory workflow by setting clear roles inside Wholesale Suite. One practical approach is to create a role called “Consignment Partner.” This lets you group these accounts and treat them differently from your standard wholesale buyers.

Once the role is set, you can limit which products they see or order. This helps you stay in control of your inventory management process because you choose which SKUs enter each location. It also helps you manage consignment inventory with fewer mistakes since each partner only sees the items assigned to them.

Use wholesale pricing and rules to protect margins

After setting roles, you can assign prices that fit the model. Since consignment requires more steps than standard wholesale, you may set slightly different prices for these accounts. Wholesale Suite lets you apply these adjustments per role, which helps you shape terms that match the extra work involved in managing inventory across several locations.

You can also use MOQs and minimum order values to guide replenishment orders. This prevents small, scattered requests that take too much time. Clear rules help both sides understand the flow of restocking without turning the model into a burden.

Make reorders easy with a wholesale order form

Replenishment becomes easier when partners have a simple way to order. Wholesale Suite includes a one-page order form that lets consignment partners request stock quickly. They can choose case quantities, assortments, or their regular picks without sending long emails. This keeps shelves from running empty and helps you maintain a steady movement cycle.

A clear order form also helps you manage consignment inventory more effectively because you gain cleaner records of what each partner asked for. This reduces confusion near reconciliation time.

Align payment terms with reconciliation timing

WooCommerce paired with Wholesale Payments gives you room to set payment terms that match your reporting cycle. You can assign NET terms to consignment roles so their invoices match the timing of your counts. This keeps your numbers aligned with what you expect to receive.

Clear terms also prevent confusion when it is time to settle. Since the store only pays for sold items, the timing must match your count schedule. This supports smoother reconciliation because both sides follow the same rhythm.

Onboarding and communication flows

You can also shape a simple onboarding flow inside your store. Start by tagging accounts during registration so you know who is on a consignment model. After that, you can send onboarding emails that explain how reorders work, how reporting should be sent, and what happens to unsold stock.

Good communication keeps the setup stable. When everyone knows the rules from the beginning, you avoid misunderstandings that show up later. This also supports your wider inventory management plan because you stay updated on movement across locations.

Choosing Between Consignment And Standard Wholesale (Decision Framework)

Key questions to ask before saying “yes” to consignment

Before you agree to a consignment inventory setup, you need a clear way to judge if the account is worth the work. One helpful question is whether the store already shows strong interest in products similar to yours. If their customers already buy these types of items, movement will be easier to predict.

Another important question is whether you can handle a longer cash cycle. Since payment only comes after items sell, you must be sure your finances can support the wait. You also need to judge your capacity to handle regular counts, reports, and follow-ups. If your inventory management routine is already stretched, the model may add stress that affects other parts of your business.

You also need to decide if the account offers long-term value. A strong location with steady foot traffic may justify the extra work. A low-volume store may not give enough movement to make the setup worth your time.

Simple decision matrix

A decision matrix helps you stay objective. When an account has strong strategic value and a proven record of good sales, it becomes a clear candidate for a small trial under this model. You can track real numbers and decide based on data instead of guesswork.

On the other hand, accounts with weak sales history, low traffic, or unclear reporting habits may not be the right fit. In these cases, a standard wholesale order protects your time and keeps your inventory management process stable. This also helps you manage consignment inventory with more control since you focus only on accounts that can support the setup.

How to transition off consignment

When the setup works well, you can slowly move the account into standard wholesale. This shift becomes easier when you have clear sales history. You can show the store how much movement the items gained over time. This makes it easier to set MOQs and regular order cycles.

A clear transition plan helps both sides avoid confusion. It also keeps your inventory management process balanced because fewer items sit outside your warehouse without immediate payment.

Conclusion And Next Steps

When you look at how consignment inventory works across different wholesale settings, you start to see that the model is neither good nor bad by default. It becomes helpful when it fits the right account and it becomes a burden when the structure is weak. In my experience helping brands shape their wholesale systems, the best results come from partners who give clear rules before sending even a single box. They stay realistic about movement and treat the setup as a controlled test rather than a shortcut to quick sales.

Let’s take a look at what we’ve tackled in this article so far:

- What is consignment inventory?

- Why wholesalers consider consignment

- Risks, downsides, and common consignment mistakes

- Designing a solid consignment inventory agreement

- Approximating consignment workflows with Wholesale Suite

- Choosing between consignment and standard wholesale

If you want to try this approach in your own store, start small and stay organized. Pick one or two accounts that show real potential. Set clear rules for counts, reporting, and returns. Shape your WooCommerce store in a way that supports your workflow, especially if you use Wholesale Suite to group roles, set pricing, and manage reorders.

When you treat the model as part of a larger inventory management plan, you gain more control over movement and reduce the risk of silent losses. This helps you decide if the setup deserves a long-term place in your business.

Frequently Asked Questions

What is consignment inventory in simple terms?

Consignment inventory is a setup where the wholesaler keeps ownership of the products while the items sit in the retailer’s store. The store only pays for what sells. This gives the buyer low risk while you take care of managing inventory and tracking movement.

What is the biggest downside of consignment?

The biggest downside is slower cash flow. Since payment only comes after sales, your money stays tied up in the stock that sits outside your warehouse. You also face risks like missing items, unclear reports, and slow movement.

How do I protect my margin in a consignment setup?

Clear rules protect your margin. You need written terms for counts, returns, discounts, and payouts. You also need a way to track how each location performs. This keeps the model predictable and prevents quiet losses.

How often should I check or reconcile consignment stock?

Monthly checks work for many wholesalers. High-volume stores may need weekly checks. Regular counts keep your numbers accurate and prevent problems near settlement time.

When should I say no to consignment?

Say no when the store has low traffic, unclear reporting habits, or weak sales history. These accounts add work without giving you enough movement. You should also avoid this setup when your cash flow cannot support long waits.

Is consignment a good long-term model?

It depends on the account. Some stores perform well and stay in the program for years. Others work better with short test cycles. The setup works best when you start small, track movement with care, and only expand when the numbers make sense.